Closing tools

standard 2.02, 2.00 (other standards to be agreed)

We produce a complete tool for closing machines produced by companies such as:

Ferrum F240, Ferrum F308, Ferrum F506, Ferrum F708, Ferrum F812, Ferrum F918, FIGGIE, SIMA 2000/6, COMACO, ANGELUS, FMC

Specification

The set of tools includes:

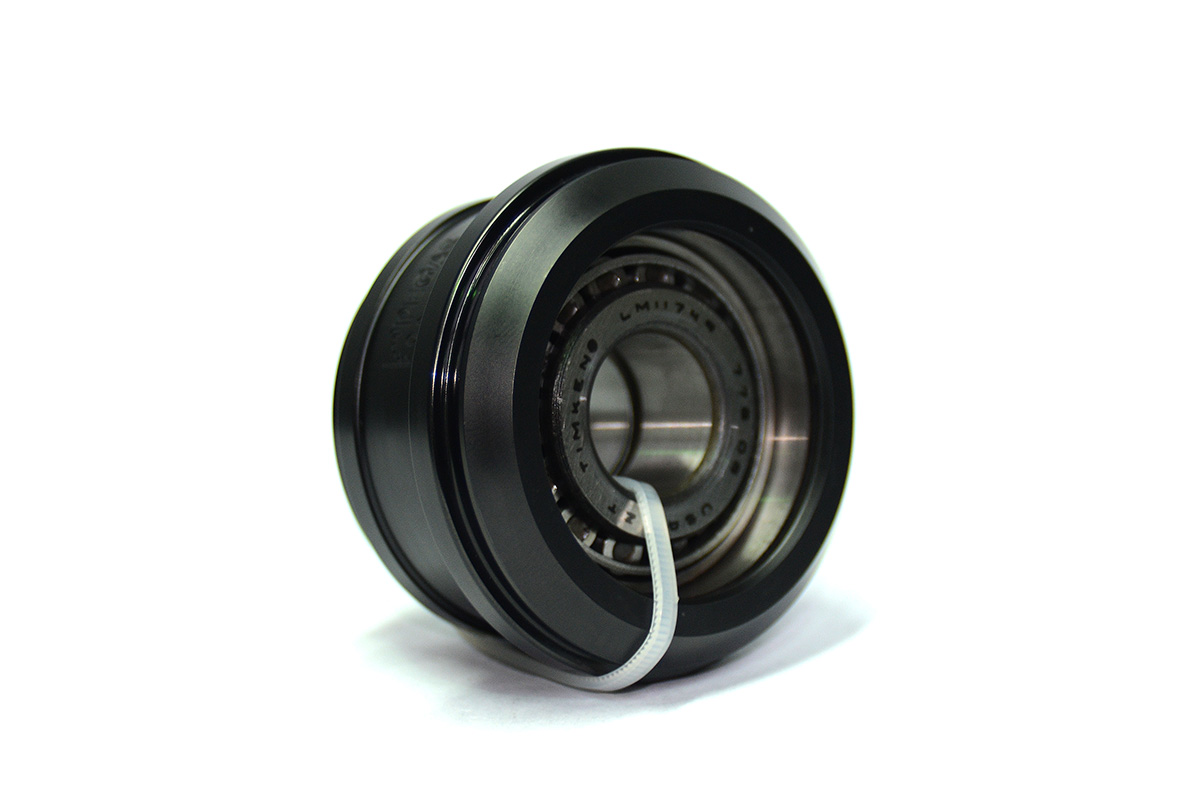

- Roll I crimping operation of the can’s lid along with the TIMKEN bearings, seals, lid and seger.

- Roller II operations crimping of the can’s lid along with the TIMKEN bearings, seals, lid and seger.

- Centering head.

Tools are made of the stainless steel with a chromium content of over 18%, and the steel produced with powder metallurgical technology with a chromium content above 20%.

In a further process, they are subjected to a heating treatment due to achieve a hardness of the 58-62 HRC and a maximum abrasion resistance. After the heating treatment, rolls and the head are being subjected to the processes of applying a special coating with thickness of only a few thousands of millimeter.

They reduce the coefficient of friction, which increases tools’ life span. Coating color depends on the type of materials used (matched depending on the needs), they differ in the value of the micro hardness and the maximum working temperature. Applying the coat is the last technological process.

The construction of a roll

Corrosion resistant steel

STEEL POWDER

ON REQUEST

Coatings

Used for coating tools CVD (Chemical Vapor Deposition) methods offer very hard, wear and corrosion resistant coating of nitrides and oxides on the steel foundations, diametrical increasing the tool life span.

Resisting and prolonging tools’ life span coatings:

Bearing

Hybrid bearings extend fivefold the time of use, it allows for the maximum use of closing tools without the need to replace the bearings and reducing periodicity of their lubrication.